As an advocate for integrating technology into bridge applications, I am often asked why we should explore new technologies when we have been designing and constructing bridges for decades using established workflows and tools. While this perspective is understandable to some extent, it fundamentally overlooks a critical issue: our industry, and the world, is changing around us, and we have largely identified the efficiencies of our traditional processes.

One fact that I believe all industry professionals can agree on is that we are increasingly looking to achieve more with fewer resources, as budgets continue to tighten and the labor force declines.

Leveraging Advancements in Technology

One method we have at our disposal to combat these challenges is to leverage the advancements in technology within our industry and closely related industries. There are new tools and methods available now that can improve the efficiency and effectiveness with which we design, build and maintain our structures. Some examples include:

- Unmanned aerial systems (UAS) – or drones – for bridge inspection applications, high-resolution construction imagery, and point cloud data collection through photogrammetry or light detection and ranging (LiDAR).

- Automated construction tools such as machine guidance and robotics for tying, and even placing, reinforcement in bridge decks.

- Building Information Models (BIM), which can be used for multiple applications within projects, including generating deliverables, clash detection, constructability analysis and many other use cases.

A Targeted Approach

This does not mean, however, that we need to implement every piece of technology immediately in all situations. We can adopt a targeted approach for specific bridge applications, applying new technologies in a step-by-step manner. For instance, a low-risk, low barrier of entry activity that can be implemented now, particularly for large and complex bridge structures, is the development of at least a “base” level BIM component for these projects.

Starting with a Base Model

A base model is typically started early in the design process when preliminary engineering and structure alternatives are developed. With the design and model-authoring software readily available today, creating these models is efficient when the process is integrated into an overall model-centric design approach in which a 3D model is used as a central repository of digital data that is used and re-used for multiple design activities.

Starting with a base model is beneficial for several reasons:

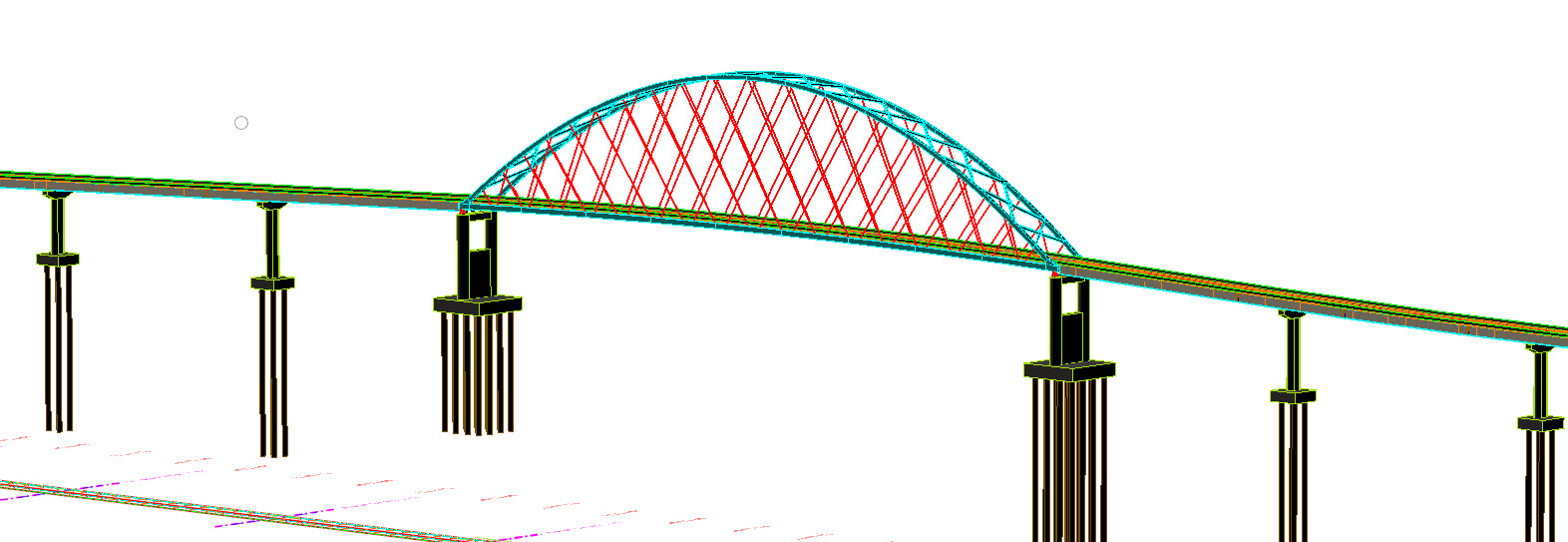

- A 3D model of a signature structure or structures in a critical corridor is typically needed for public outreach strategies, and a BIM “engineering-grade” model can be used as an accurate foundation for visualizations and combined with UAS imagery and point cloud data for crafting public-facing messages as well as additional design and construction applications.

- The model can serve as a “single source of truth,” adding value in preliminary and final design engineering applications, such as drawing development, quantity generation and coordination tool between disciplines.

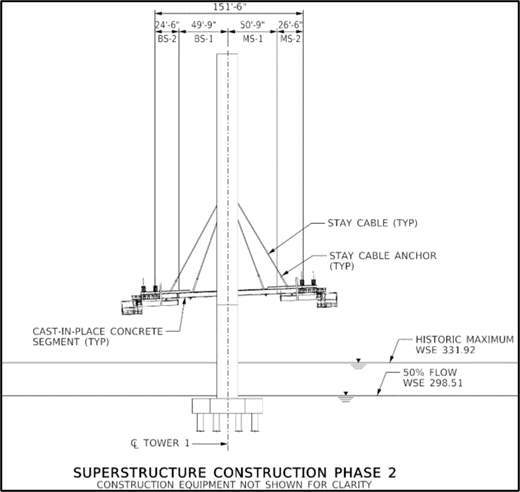

- The model can automate clash detection and aid in constructability analysis serving as a dynamic tool to identify and resolve potential conflicts in areas of high concern and/or congestion, and also can be effectively integrated with construction schedules to produce a “4D” visual model simulating the proposed construction activities sequentially.

It is important to note that models can and should be right sized for the needs of the project, and additional detail and data can always be introduced effectively if a base model exists. Creating and updating these models from preliminary design through final design and beyond provides added value and return on the initial relatively small investment to create the base models in the first place. However, creating models as an afterthought or re-creating them from 2D plans produced through traditional workflows is time-consuming and reduces the return on investment (ROI) of BIM significantly.

The Future of Bridge Technology

While the adoption of these technologies is becoming more common, incorporating at least a basic level of BIM into projects is not yet standard practice. Major projects can span several years, and the capabilities of what we can do with data can change significantly from the start of a project to its completion, given the rapid pace of technological development. Several groups, including the AASHTO Transportation Pooled Fund - BIM for Infrastructure TPF5-(480) project in which the Michael Baker team is helping to lead, are actively researching and implementing ways to more seamlessly use and exchange the digital data produced by today’s software and tools. There is also exciting research and early implementation on post-construction applications in digital as-builts and additional asset management applications such as digital twins. However, the data cannot be leveraged if it is not produced and incorporated as part of the project now.

Looking Ahead

While we might be comfortable with our traditional workflows and tools, our industry must continue to innovate. There are numerous opportunities to leverage proven technologies to advance our field and better serve the traveling public. This trend is here to stay, and emerging technologies such as AI and Machine Learning will only continue to disrupt our industry. By embracing these advancements, we can ensure that we are not only keeping up with the world around us but also paving the way for a more efficient and effective future in bridge design, construction and maintenance.