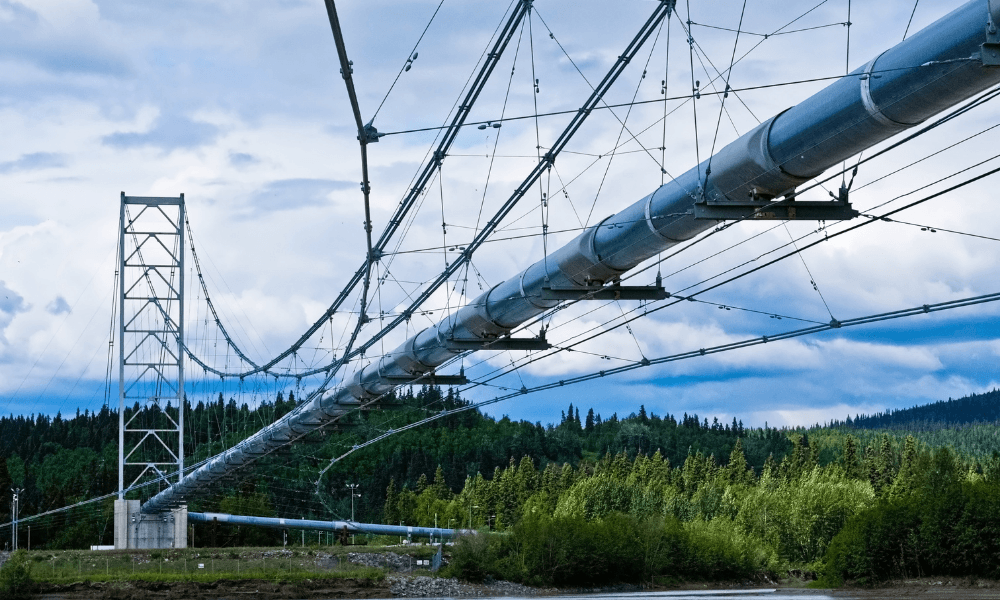

As we celebrate Michael Baker’s founding month throughout May, we are shining the spotlight on one of our firm’s most iconic projects: the Trans-Alaska Pipeline System (TAPS). Michael Baker was a major engineering consultant for the design of the 789-mile-long, 48-inch diameter pipeline, which traverses three mountain ranges, three major earthquake faults and hundreds of rivers and streams. The four-year, $7.7 billion construction of TAPS was one of the first large-scale, privately funded projects in the world and was built through the Alyeska Pipeline Service Company, a group made up of seven oil companies.

We continue to do groundbreaking work in Alaska related to cold regions engineering and major projects along the state’s North Slope with the same spirit of innovation and commitment that inspired our work on TAPS.

Did you know?

- Since pipeline startup in 1977, TAPS has successfully transported more than 17.6 billion barrels of oil from Alaska's Arctic Coastal Plain to the Port of Valdez, the northernmost ice-free port in the U.S.

- TAPS currently averages 450,000 barrels of oil per day.

- Approximately 50% of the pipeline is above ground.

- The pipeline was engineered in a zigzag pattern, so that it becomes flexible if needed, like during an earthquake.

Between 1969 and first oil in 1977, Michael Baker experts dedicated more than 2.5 million man-hours in civil, structural and mile-by-mile pipeline design north of the Yukon River. We were also responsible for civil design and survey of more than 200 access roads, airstrips and pipeline bridges, as well as design and survey for the U.S.’s northernmost Dalton Highway, a 358-mile haul road that links TAPS and Alaska's North Slope oil fields to Alaska’s road system.

Keith Meyer, Chief Engineer - Oil & Gas Pipelines, was a part of this original team that designed TAPS. We sat down with him to learn more about his work on this notable project.

What stands out most to you about designing the TAPS?

The tremendous challenge of the state and its climate stand out to me. Alaska is largely unique in the U.S. experience and is very remote. Our team worked to meet unique engineering challenges in an incredibly short time and designed a system that still serves its purpose after half a century.

What was the biggest challenge you faced throughout the project and how did the team overcome that challenge?

Within Michael Baker, there were many new, never-before-applied, innovative engineering designs and analytics that we used in this project. This included pipeline aboveground supports with passive built-in refrigeration, seismic design to meet some of the highest design seismic motions on record, waterway designs with almost no historical records and material designs to withstand extreme cold temperatures.

As a junior engineer, a big challenge for me was the finite element structural analysis that we performed for the project. We used a dial-up phone connection to a remote server running with the computer program. This was the first time this was done in our department, and certainly one of the first times throughout the company. We had to learn how this would work from scratch, thankfully with much support from our co-workers. Now it is universally used – but this wasn’t the case nearly 50 years ago.

What are some of the most innovative features of the project?

Some of the innovative features included widespread use of geothermal information to ensure the hot crude oil pipeline would not adversely affect the in-situ local environment; detailed seismic analysis – in its relative infancy at that time – in consultation with leading University advisers; considering the behavior of structural elements beyond the usual stress range that codes considered at that time and using survey results in computer analyses.

How does this project exemplify We Make a Difference?

Our team at Michael Baker really came through on the project. We scoured the country for trained personnel for the many field activities, designed the road to transport materials north of Fairbanks (“the haul road”) in record time, supported Pipeline Service Company in cross-country pipeline design, designed and built several bridges and continued in post-construction support. It is no surprise that TAPS quickly became one of Michael Baker’s signature projects.

How did working on this project impact your career?

Working on my doctorate at Carnegie Mellon University, several of the seismic concepts that we used in this project gave me a better understanding of my thesis, which was based on seismic analysis. Once I obtained my doctorate, Michael Baker relocated me to California to work on a new proposed Alaska gas pipeline project in which the experience of my first Michael Baker years helped greatly. I think those early years of pushing new limits with co-workers pulling together to successfully complete the project made me think of Michael Baker as “home.”

The TAPS project was recently featured on American Built, a program on FOX Business highlighting engineering marvels across the country. View a clip here: https://www.foxbusiness.com/shows/american-built

Check your local listings or sign in with your TV provider to view the full episode on FOX Nation: https://nation.foxnews.com/american-built/