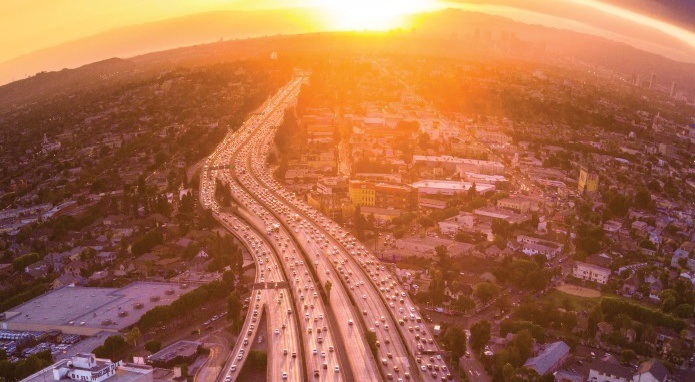

The collaborative design-build process behind the recently launched Interstate 10 highway project in Southern California is already running in the fast lane

From the Summer 2019 issue of Signature

The phrase “threading the needle” has multiple meanings. Its literal meaning is to guide a piece of thread through the eye of a sewing needle. Its social meaning is to skillfully navigate a complex situation – such as Michael Baker International’s current $672.9 million Interstate 10 Corridor Express Lane design-build project in Southern California.

The project includes widening an 11-mile stretch of high-volume, high-speed, multilane freeway for a new tolled Express Lane facility – through a heavily populated area with hundreds of commercial and retail properties bordering both sides – while still keeping five lanes in each direction open at all times, and doing it cost-efficiently, time-efficiently and safely.

To accommodate the added Express Lanes, the project proposes to widen or replace 20 bridge structures, including six overcrossing replacements, two undercrossing replacements, seven undercrossing widenings and five bridge widenings over channels. The project adds 81 retaining walls of various types, including subhorizontal ground anchor walls, soldier pile walls, soil nail walls, standard walls and sound wall barriers.

As lead designer, Michael Baker is responsible for managing the overall design process, which includes ensuring that the design meets the schedule and established design criteria, as well as interfacing directly with the design-build contractor, Lane-Security Paving Joint Venture (LSPJV), to integrate design and construction.

Michael Baker also is responsible for roadway, structure, drainage, maintenance of traffic, intelligent transportation systems, tolling design, landscape architecture and survey activities. The San Bernardino County Transportation Authority (SBCTA), California Department of Transportation (Caltrans) and numerous municipalities along the route are involved in the project.

While construction is not expected to begin until early 2020—and wrap up in 2023—Michael Baker’s diverse 80-member project team has been hard at work for months leveraging experts from across the country and from multiple disciplines including highway, bridge, drainage, landscape architecture, survey/GIT and permitting to coordinate this integrated effort.

“This is quite a large project, with many moving parts,” said Roadway Design Lead Danny Walden, P.E., in Michael Baker’s Ontario, California, office. “One unique aspect is the full removal and replacement of the outside two lanes in both directions as part of the project. This has added complexities to the sequencing of the project construction and the handling of vehicular traffic through the work area. Also, a number of third-party utilities need to be relocated, making this a challenging project for design and construction.”

I-10 is a vital transportation route, carrying more than 263,000 vehicles each day. As the region continues to grow, travel demands will exceed the capacity of the transportation corridor, causing an increase in delays, accidents and congestion. By 2045, daily traffic will increase to 350,000 vehicles, a level the current corridor is not designed to accommodate.

“The I-10 corridor project is critical to our region to reduce congestion at a time when we are growing faster than ever,” said Mike Barnum, SBCTA Representative. “We are excited to be working with the Federal Highway Administration, Caltrans, LSPJV and Michael Baker’s design team on this important project.”

“This project represents our ability to deliver the ‘next level’ transportation infrastructure project in size and complexity, as well as our ability to execute a large complex design-build project,” said Malcolm Dougherty, P.E., National Practice Lead - Transportation. “Southern California stakeholders and the industry nationally took notice and it will lead us to greater opportunities to work on impactful transportation improvements across the country in the future.”

“We are excited to be involved in this project, which will add options for congestion management through this very busy corridor,” said Jonathan Den Hartog, Supervising Transportation Engineer at Caltrans. “We are coming off a very successful design-build project with SBCTA and are hoping to replicate that success with the I-10 project.

Maintaining traffic flow through the construction zone, once the project is underway, will probably be one of the more challenging aspects, but we are looking to harness the ideas and input of the team to keep the impacts to area motorists as few and as unobtrusive as possible.”

PARTNERING FOR SUCCESS

“Fortunately for us, we have had a working relationship with Caltrans even before we got the notice to proceed on this project,” said Michael Baker’s Technical Design Manager Terry Ogle, P.E. “As the initial technical drawings were shown, I was impressed with the level of expertise and willingness to work with us on specifics. Taking such a practical approach through the design-build process has been beneficial.”

A Technical Working Group holds weekly meetings with Caltrans and SBCTA, where specific topics in need of answers can be aired and addressed, said Ogle.

“It is an opportunity to really roll up our sleeves, throw out possible solutions and ideas for discussion,” he said. “We understand what the client is after, and it has been very good to work with them to meet the needs of their constituents.”

“Although we are early in project development, having the entire team colocated at one office has allowed us to form relationships that will help the project be successful,” said Jason McLear, LSPJV District Manager.

The Michael Baker team highlighted one part of the overall project as especially challenging – the Sixth Street Bridge.

“The Sixth Street Bridge is unique because of how it skews across the freeway on an angle and the proximity of residences and local streets relative to each end of the bridge,” explained Steve Huff, P.E., Michael Baker’s Regional Practice Lead – Transportation, who also serves as the lead client contact for the project. “That makes it challenging for a number of reasons – bridge depth, vertical clearance, impact on local properties and roads – in how it needs to be designed and built.”

While the final plans are still being worked out, a potential solution the collaborative designer-contractor team has identified through the design-build process calls for a spliced-girder construction over the freeway. “That is a big deal because it is out of the norm and not something that everyone is immediately familiar with,” said Huff. “It brings a heightened level of attention. However, in working with LSPJV, SBCTA and Caltrans, this solution is expected to work best.”

That sort of out-of-the-ordinary, innovative thinking can blossom most effectively when all minds involved in a problem can openly and frankly contribute. The design-build approach has been proven to create and foster that exact environment. The importance of relationships among organizations and individuals around the design-build table cannot be understated, and the I-10 project enjoys numerous tightknit relationships – which enhance trust and collaboration.

“The prior connections present among the players on this project have proven to be invaluable,” said Huff. “It starts with our team’s experience having successfully worked with Caltrans District 8 in San Bernardino, California, for several years and extends to the many individuals representing SBTCA as the project sponsor. With these relationships and expertise from so many other design-build projects and experiences, our presence on this project adds a lot of credibility.

“There are so many advantages design-build brings to the table,” Ogle said. “The agencies start with a project concept, then we bring in the design-build aspects. Designers and contractors work through a complex staging of how to do the job, analyzing and thinking things through together. The beauty and benefit of design-build is that you get that back-and-forth energy. Projects can move faster working alongside each other. It is a good formula to get things done.”

Even when – and perhaps especially when – you have to thread such a complex, intricate, economically vital needle as Interstate 10.