Chain of Rocks Bridge: Applying Proactive Risk-Based Maintenance

According to the American Society of Civil Engineers’ (ASCE) 2021 Report Card for American Infrastructure, 42% of our nation’s 617,000 bridges are at least 50 years old. How we preserve and maintain bridges has drastically changed in the last half century alone thanks to advances in engineering tools and technology. Successful bridge programs seek a balanced approach to rehabilitation and replacement, and for those bridges nearing the end of their service life but not yet scheduled for replacement, owners may face challenges with maintenance of critical members and connections with outdated, legacy details.

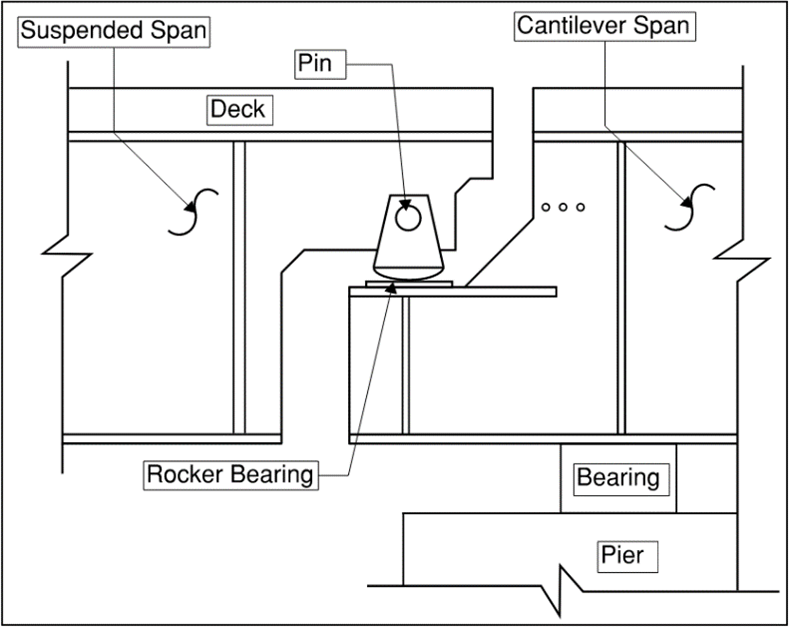

One such bridge was the Chain of Rocks Bridge, a multi-span continuous, cantilevered steel girder bridge carrying I-270 over the Mississippi River. A cantilevered design means that the girders (main supporting members) run continuously over interior supports and have a suspended span that rests on the leading edge. This adds desired continuity and creates a hinge point in the girder that provides a relief point and simplifies the behavior and analysis. This was a common design strategy in the 1960s era prior to the availability of modern computer analysis tools.

Constructed in 1966, the Chain of Rocks Bridge crosses the Mississippi River between Granite City, Illinois, and St. Louis, Missouri. The bridge supports two separate, parallel roadways, one carrying traffic eastbound and one carrying traffic westbound. The roadways have different superstructures – or the horizontal deck support structure above the bearings (devices that girders rest on) – but share a common substructure – the vertical support structure below the bearings.

Cantilevered steel plate girder bridges like the Chain of Rocks Bridge often use special details to provide the hinge behavior, which can allow free rotation and release stress while accommodating variations in movement, shrinkage and temperature. This bridge utilizes a detailed called a shiplap connection which forms a type of “shelf” at the cantilever end for the suspended span to rest on with the use of a bearing. These joints are no longer used in modern bridge design since the philosophy today is usually to eliminate joints as issues have frequently developed in these legacy connections in the form of fatigue cracking at locations with high stress concentrations.

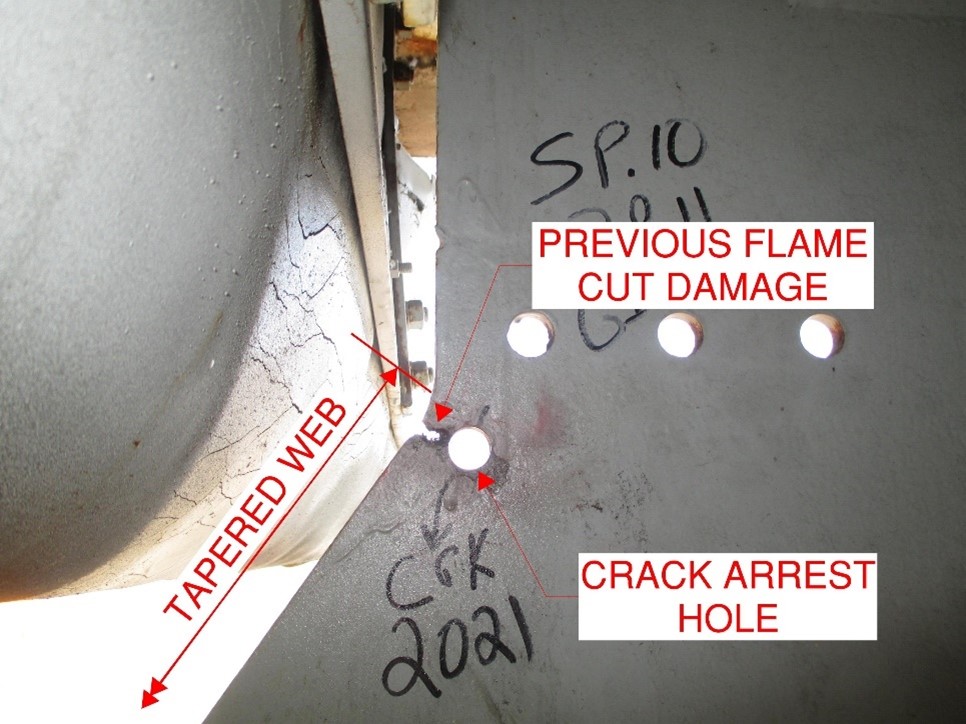

Michael Baker International was contacted by the Illinois Department of Transportation (IDOT) regarding a fatigue crack found at one of the Chain of Rocks Bridge’s shiplap hinge connections. The crack initiated at a sharp discontinuity in the web plate end, where the plate transitioned from being vertical to sloped.

It was determined that detailed structural analysis was needed to verify the safe load capacity of the connection (the maximum amount of weight the bridge could safely carry), to ensure no immediate safety concern existed and to determine any need for remedial actions. Additionally, many similar imperfections also existed in the other shiplap connections throughout the bridge which required careful evaluation. Our team determined that fatigue evaluation as well as strength evaluation of the shiplap connections was necessary.

In most cases, a fatigue crack in a Non-Redundant Steel Tension Member (NSTM) should be considered a critical finding, which is defined by National Bridge Inspection Standards (NBIS) as requiring immediate follow up or action. Fatigue cracking often will continue to propagate, and for NSTMs, this can result in total or partial collapse. Refined analysis revealed that fatigue life in these shiplap connections were fully expired and more cracking was expected at other locations, convincing the owner that a retrofit was necessary and that frequent in-depth inspections should be done until the retrofits could be completed.

Notably, IDOT had programmed this bridge for replacement within five years and therefore, any retrofits should not be too costly or impact traffic. Our team provided a cost-effective solution to keep traffic flowing by developing and installing innovative retrofit details at all accessible locations to preemptively mitigate the risk of additional cracking. Repairs included reprofiling the web-free edge and adding supplemental bolted strap plates to reduce fatigue stresses and achieve infinite life so additional repairs wouldn’t be necessary before the bridge was replaced in the near future. Load rating analysis using full nonlinear finite element analysis (FEA) was also performed on the existing connection and with retrofits applied to verify capacity. These repairs were performed at 11 locations by IDOT.

Throughout the process, our team identified several key learnings:

- Legacy details in bridges are often more vulnerable to deterioration and maintenance issues. They should be given greater attention in inspection and evaluation and maintenance solutions.

- Repairs to extend service life in existing bridges should be done with full consideration of risk.

- The national engineering standards and specifications are still limited in their application of refined analysis techniques, which may require additional interpretations and engineering judgement for proper decision making.

We dive into greater detail on this project in the white paper, “Evaluation and retrofit of steel girder shiplap connections*,” written with the cooperation of IDOT.

*© Brian Kozy, PhD, P.E.; Jonathan Beckstrom, P.E.; Tim Armbrecht, P.E. The definitive, peer reviewed and edited version of this article is published in Bridge Structures 19 (2023) 103–119, DOI:10.3233/BRS-230212, IOS Press