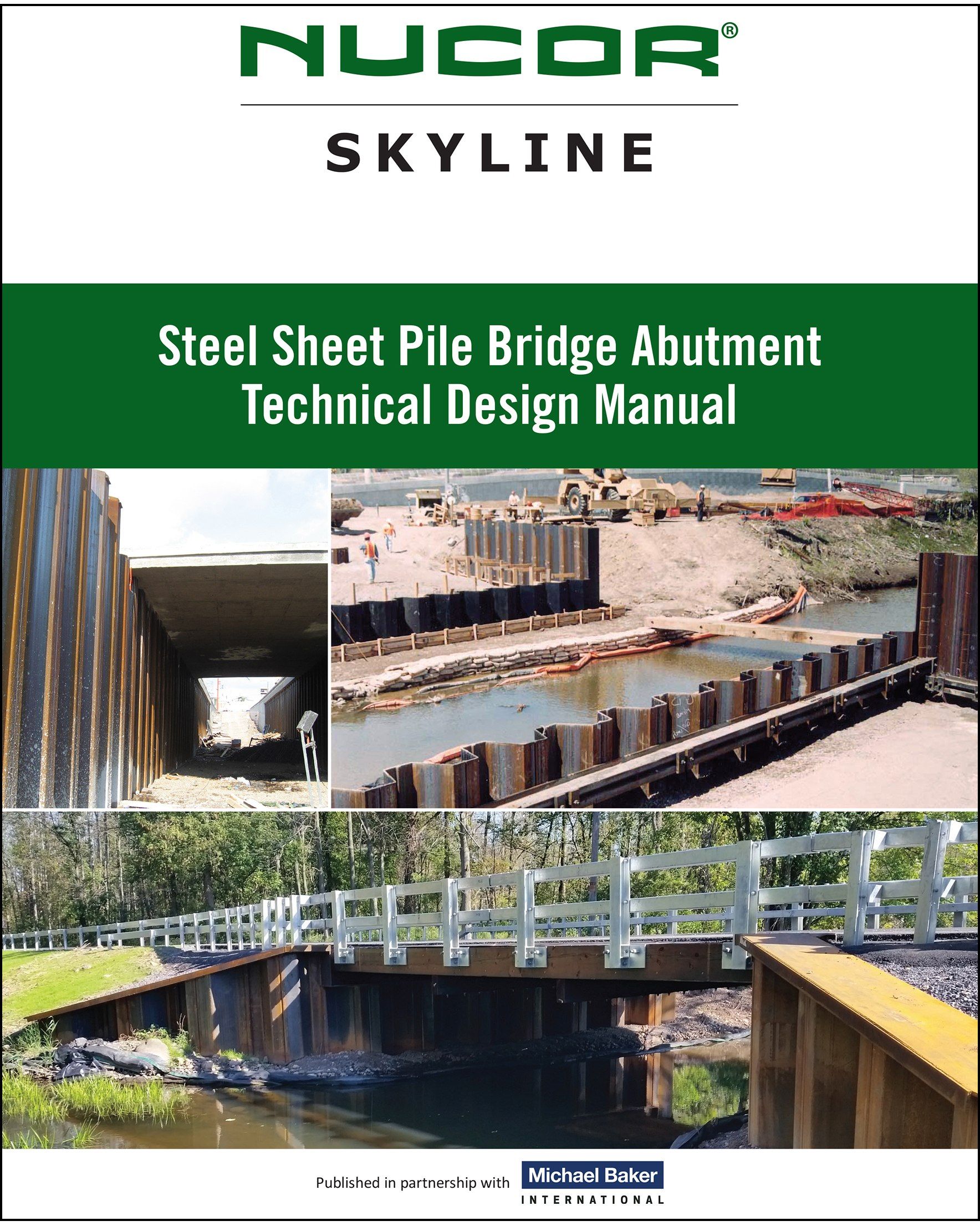

*Photos courtesy of Nucor Skyline

The new Steel Sheet Pile Bridge Abutment Technical Design Manual is a breakthrough in the American engineering community. Sponsored and published by Nucor Skyline, in partnership with Michael Baker International, the trailblazing manual brings together, for the first time, information and design guidance on sheet pile bridge abutments.

We caught up with Errynne Bell, PE, manager, business development at Nucor Skyline and Rich Schoedel, PE, primary investigator and bridge technical manager with Michael Baker International, to learn more about the new manual and its contributions to the engineering and construction industry.

Why was this research conducted? Please explain the driving need.

While some sheet pile bridge abutments have been constructed in the U.S., they have not gained widespread use, primarily because of the lack of established design guidance. To date, the benefits of using sheet pile abutments and associated technical design guidelines have been largely undocumented within U.S. engineering practice. Most engineers are familiar with methods for the design of sheet piling under primarily lateral loads, and specifically in temporary applications. Steel sheet pile abutments force the engineer to consider the pile’s ability to not only resist lateral loading, such as earth pressures, but also vertical loading and to do so long-term.

Our research synthesizes the body of knowledge on sheet pile abutments available within the engineering practice worldwide. Now, technical information on this solution is compiled into one document and available to the U.S. engineering community.

Readers can gain a full understanding of the benefits this method has to offer. In a bridge construction environment where funding is stretched thin and every day counts for user delays, steel sheet pile abutments pair well with Accelerated Bridge Construction (ABC) technologies to help owners achieve their goals in maintaining our nation’s infrastructure. Steel sheet pile abutments can be built quickly, are cost-effective and often result in minimal disturbances to the environment, nearby properties and travelers. The approach contrasts conventional bridge abutment construction methods comprised primarily of cast-in-place reinforced concrete that can be expensive, time consuming and cause excessive disturbances to right-of-way and nearby waterways.

Tell us about the research process. How did you approach it and evaluate the information?

Once the need for the technical design manual was established, we outlined the information a designer would require to successfully design a sheet pile abutment. We also discussed any concerns over the concept with various bridge owners to fully frame where the knowledge gap existed. Michael Baker International’s subject matter experts in structural and geotechnical engineering conducted a thorough literature review of the available academic research worldwide, including scholarly journals, conference proceedings and design codes. The manual was structured much like the AASHTO LRFD Bridge Design Specifications, intentionally mirroring the breakdown of sections, such as Loads, Structural Analysis and Member Design, etc.

In addition, the design team recognized, from our research, that there would likely be hesitation and concern over special topics, such as installation, corrosion of the piles or the design of the pile cap. We thoroughly examined and documented these topics. Lastly, we knew that a manual alone would not serve engineers seeking practical and rapid implementation, so we created a detailed flowchart and several design examples to demonstrate the use of the guidelines. The creation of these examples led the team to research areas more deeply. We conducted numerous sensitivity and parametric studies relating to the design recommendations to further clarify and streamline the guidelines.

What are some of the key takeaways the manual reveals?

Important steps in the design process are revealed, such as selection of the appropriate structural analysis method, designing for stability (buckling), accurately assessing corrosivity risks, how to properly assess slender sheet piles, including cold formed members and how to provide proper corrosion protection, to mention a few. All stages of construction are important to the design and analysis of sheet pile abutments, and the design guidelines outline how and when to evaluate these.

Steel sheet pile abutments are considered an accelerated construction method, complementing current industry initiatives for ABC techniques. Typically, they require less excavation, backfill, concrete and reinforcing steel compared to other methods. By reducing delays and costs, sheet pile abutments can provide a cost advantage both in real construction savings, as well as in reduced user delays. In situations where an older bridge is to be replaced, the use of a sheet pile abutment may reduce or eliminate the need for long duration tasks like right-of-way acquisition, as well as costly shoring during multiple phases of construction.

It’s also a sustainable solution. A sheet pile bridge abutment is compact, allowing the abutments to be brought closer together to reduce the span length. Because of the compact nature of this solution, users can limit disruption to natural streams, and in-water permitting can be simplified or avoided altogether. Plus, steel itself is a sustainable, recyclable metal.

How can those interested in using steel sheet piles as permanent bridge abutments receive a copy of the manual?

Request a free copy of the manual by visiting the Nucor Skyline website at: https://tinyurl.com/4f5umehy